Pro Roof has grown to become one of the largest manufacturers of roofing solutions in South-Africa. The three most common and popular roofing profiles (Corrugated, IBR, Widespan) used in the roofing industry worldwide, are manufactured in-house at our various services and steel processing centres in South Africa.

We can supply all these profiles in both, Chromadek, Galvanised ZincAl and Colorplus.

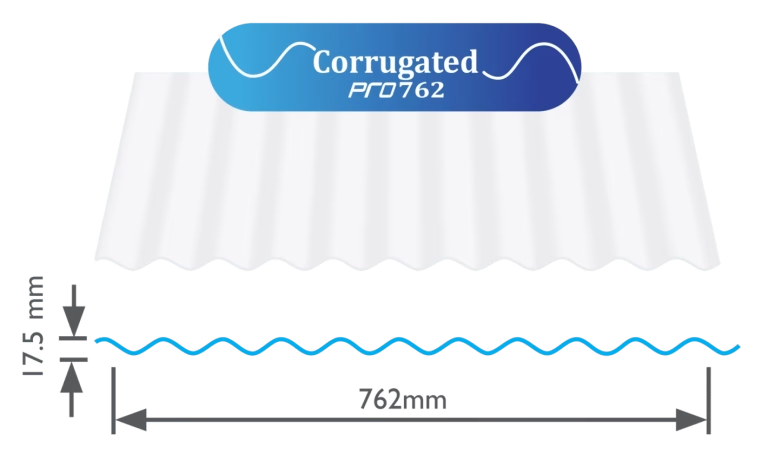

CORRUGATED PRO762 is the oldest and most widely used profile for roofing and cladding applications. This is mostly due to its ease of handling and fixing, relative strength, cost effectiveness and its successful use in the design mostly depicting the old Victorian style. Corrugated sheeting can successfully be factory cranked, curved and bullnosed to a wide range of radii to suit customer specifications. Manufactured in two sizes, namely the 8.5 and the 10.5 corrugations. Both these sizes can currently be manufactured in various thicknesses (gauges) from input material ranging from 0.23mm to 0.8mm. The effective cover of the 8.5 sheet is 610mm and that of the 10.5 sheet is 762mm.

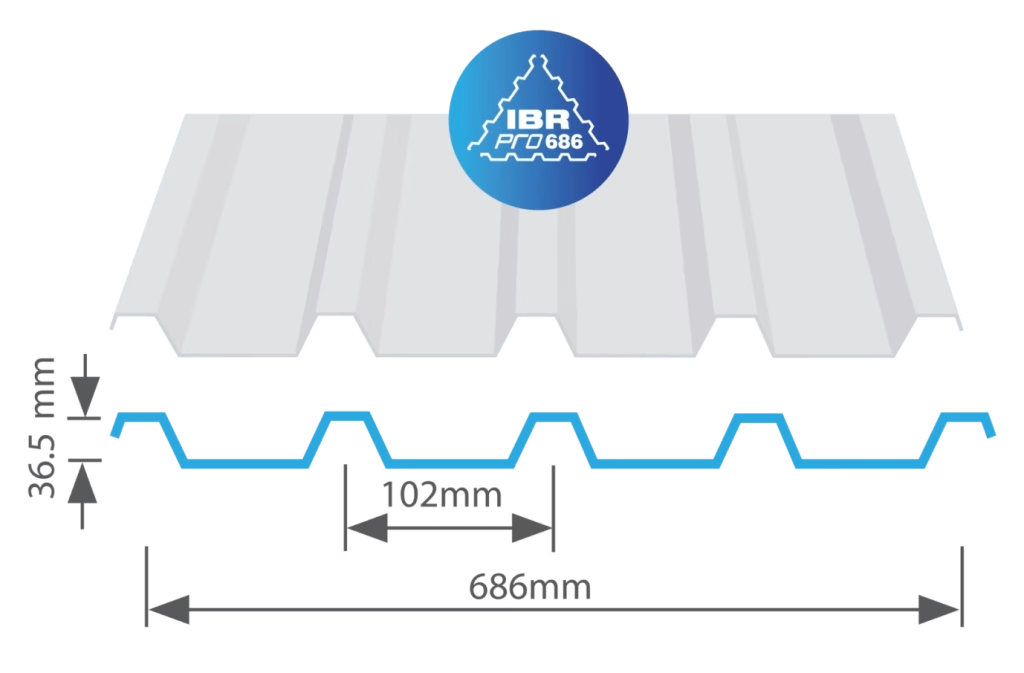

IBR PRO686 is one of the most popular profiles used for roofing and side cladding applications in the industrial, commercial and residential building industry. The bold angular appearance of this particular profile makes it a very attractive choice for industrial and domestic solutions. It’s many advantageous characteristics such as its strength to weight ratio, that provide optimum load span consistency, and the broad flutes that ensure excellent drainage, makes this a popular choice for roofing contractors.

The IBR Profile has an effective cover of 686mm and is manufactured in thickness (gauges) from input material ranging from 0.27mm to 0.8mm. This profile can also be successfully cranked, curved and bullnosed to suit customers specifications.

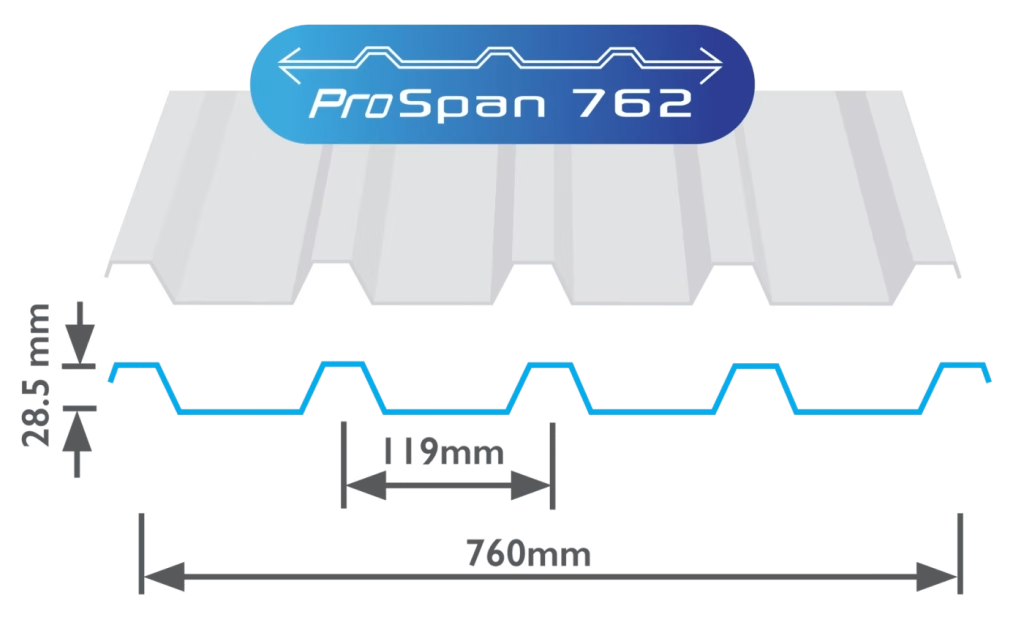

PROSPAN 762 is a roofing and cladding profile that was designed to provide the building and construction industry with an economical alternative to the IBR profile, without sacrificing the popular fluted concept so frequently used in modern architecture. The Widespan profile offers greater spans and lower slopes than the traditional corrugated profile, while providing the same cover width as the 10.5 corrugation

sheet.

The Widespan profile therefore has an effective cover of 762mm and is manufactured in the thickness (gauges) from input material, ranging from 0.27mm to 8mm. This profile can also be successfully cranked, curved and bullnosed to suit customers specifications.

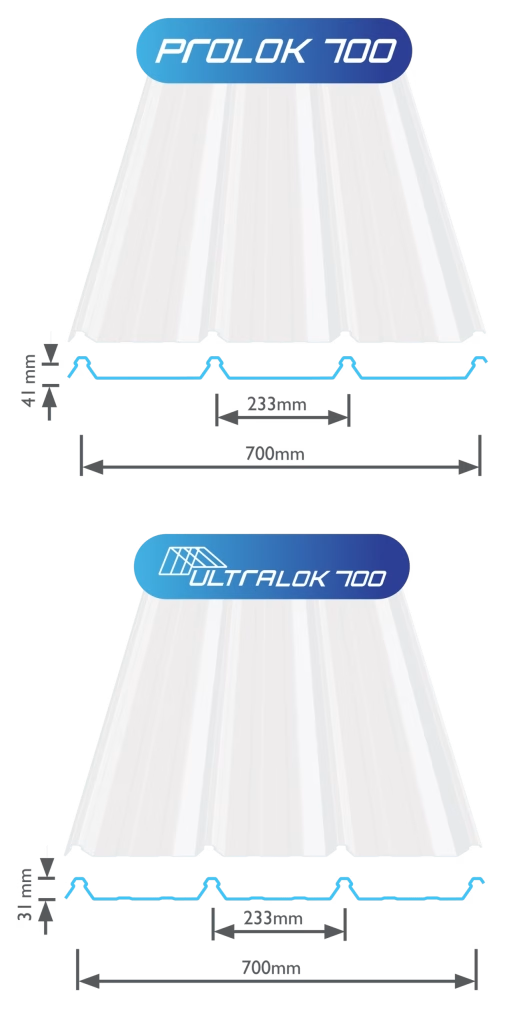

The PROLOK 700 and ULTRALOK 700 Concealed fix roofing profiles feature a strong rib for excellent spanning capacity. Created with strong ribs rising from flat pans with longitudinal fluting. Designed to provide a watertight concealed fix roofing solution to Industrial, Commercial and Residential applications. Perfectly engineered for non-piercing solar and walkway installations. Our fleet of Mobile Mills manufacture non-transportable lengths on site.

Prolok and UltraLok can be positively cranked on site and in the factory. Prolok and Ultralok can be naturally spring curved or draped on to a 36m radius convex and 60m radius concave on site.

Prolok and Ultralok Roofing is installed with ProClip and UltraClip 700 clips, the only non-abrasive clips in South Africa. Facilitating thermal expansion and contraction without compromising the integrity of the sheeting. The Anchor Towers are manufactured from Technyl C216V30 (Nylon 6.6) and fixed with wafer head screws to steel and timber purlins.

Prolok and Ultralok are manufactured from a range of input materials being Galvanized, Aluzinc, Aluminium, Stainless, mill finish or pre-painted options with a thickness range of 0,47-0,58. Input materials are perfectly matched for Developers, Architects, Quantity Surveyors, Engineers and Contractors to find the best possible application for their projects.

The concealed Prolok/Ultra Roofing product has been successfully installed on various applications exceeding with the above input materials 4,500,000m2 (5/2024).

2 Nuffield St, Duncanville, Vereeniging,

1939

SALES (016) 450 5800

✉

sales@proroof.co.za

69 Willem Cruywagen Ln, Klerksoord, Pretoria,

0200

(012) 542 7554

Visit Pro Roof PTA Website

27 Junction Rd, Parow Industrial, Cape Town,

7493

(021) 959 9000

© Pro Roof Steel & Tube.

All rights reserved.